- About us

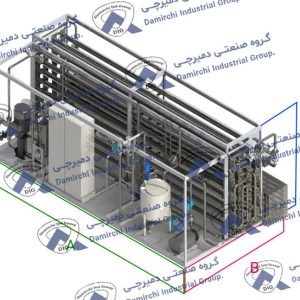

Damirchi Industrial Group, established its continuous and valuable work with the aim of improving the quality level and standards of operation in the field of designing, manufacturing, installing and setting up machinery and equipment in food, pharmaceutical and chemical industries

- Customers service

- Contact info

- Office: Unit 319, Beheshti St, Tehran, Iran

- Phone: (+98)2183872

- Factory: Baharestan Blvd, Shams Abaad Industrial Town, Tehran, Iran

- Phone: (+98)2156901030-8

- info@damirchi.com

- Fax: (+98)2156901039