Description

Pressure Vessels

Pressure vessels are enclosed containers used to hold liquids, vapors, and gases at a pressure significantly higher or lower than the ambient pressure.They are widely used in various industries such as petrochemical, oil and gas, chemical, and food processing industries. Equipment such as reactors, flash drums, separators, and heat exchangers are examples of pressure vessels.

Each pressure vessel must be operated within its design temperature and pressure, which is the pressure vessel‘s safety limits. The design, construction, and testing of pressure vessels are

extensively carried out by knowledgeable personnel and are governed by regulations because the accidental release and leakage of its contents is a danger to its surrounding environment. Some of the well-known standards are the American Society of Mechanical Engineers Boiler and Pressure Vessel Code (ASME BPVC) Section VIII, and the American Petroleum Industry (API) 510 Pressure Vessel Inspection Code.

Process Vessels

Process vessels are a broad classification of pressure vessels. These are containers where industrial processes occur, such as mixing and agitation, decantation, distillation and mass separation, and chemical reaction. The change in the internal pressure of a process vessel depends on the nature of the process carried out and the transformation of the substances involved.

Distillation columns

Distillation columns allow the separation of a mixture of liquids based on the difference in their volatilities. In this process, the mixture is heated to a temperature where the more volatile component transforms into the vapor phase. The height of the vessel depends on the column internals (packings or trays).

Industrial mixers

Industrial mixers are pressure vessels that are equipped with motor-powered blades to homogenize and emulsify a single or multiple substances. The substances mixed maybe both solids or liquids, or a combination. Agitating equipment operates at varying speeds depending on the extent of homogeneity.

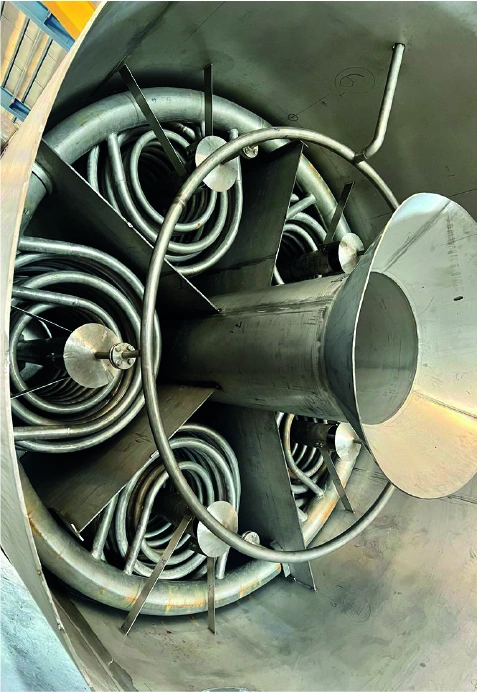

Chemical reactors

Chemical reactorsare enclosed tanks used to contain the reactants and catalysts during a chemical reaction. They are equipped with agitators to facilitate molecular contact among the reactants. A chemical reaction is usually carried out in a jacketed vessel to absorb the heat generated. Depending on the heat of the reaction, the reactants may release heat (exothermic) or absorb heat (endothermic) during the reaction. As the reactants are converted into products, the internal pressure increases if gaseous products are generated and increases even more at higher temperatures.

Storage Vessels

Storage vessels are used to hold liquids and gases for industrial purposes. The vessel may be used to contain fluids in a later process, or for storing finished products such as compressed natural gas (CNG) and liquid nitrogen. Carbon steel is the most commonly used material for storage tanks.

The commonly used materials of construction for pressure vessels are the following

1. Carbon Steel

Carbon Steel. Carbon steel is a type of steel that has a higher carbon content of up to 2.5% . Carbon steel vessels are known for their high tensile strength for a minimal wall thickness, which is suitable for a wide range of applications. They are to impact and vibration. However, carbon steel is difficult to bend and form into shapes due to its high strength. It is also more susceptible to corrosion and rusting than stainless steel since it does not contain chromium.

2. Stainless Steel

Stainless steel is a type of steel that has a higher chromium content of up to 10.5 – 30% and lower carbon content and trace amounts of nickel. They are known for their excellent chemical, corrosion, and weathering resistance which is attributed to their chromium content. A thin, inert chromium oxide film is formed at the surface to prevent oxygen diffusion to the bulk of the metal. Like carbon steel, it also exhibits high strength for a lower wall thickness. It is easier to form compared to carbon steel due to its increased ductility and elasticity.

The commonly used materials of construction for pressure vessels are the following

1. Carbon Steel

Carbon steel is a type of steel that has a higher carbon content of up to 2.5% . Carbon steel vessels are known for their high tensile strength for a minimal wall thickness, which is suitable for a wide range of applications. They are to impact and vibration. However, carbon steel is difficult to bend and form into shapes due to its high strength. It is also more susceptible to corrosion and rusting than stainless steel since it does not contain chromium.

2.Stainless Steel

Stainless steel is a type of steel that has a higher chromium content of up to 10.5 – 30% and lower carbon content and trace amounts of nickel. They are known for their excellent chemical, corrosion, and weathering resistance which is attributed to their chromium content. A thin, inert chromium oxide film is formed at the surface to prevent oxygen diffusion to the bulk of the metal. Like carbon steel, it also exhibits high strength for a lower wall thickness. It is easier to form compared to carbon steel due to its increased ductility and elasticity.