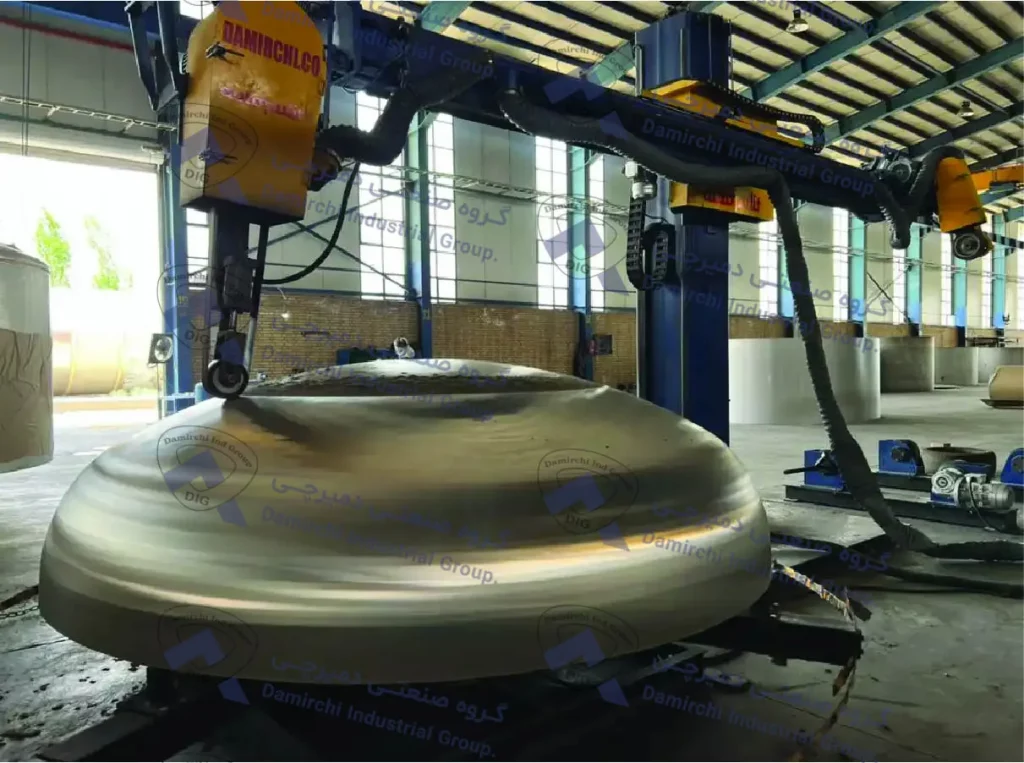

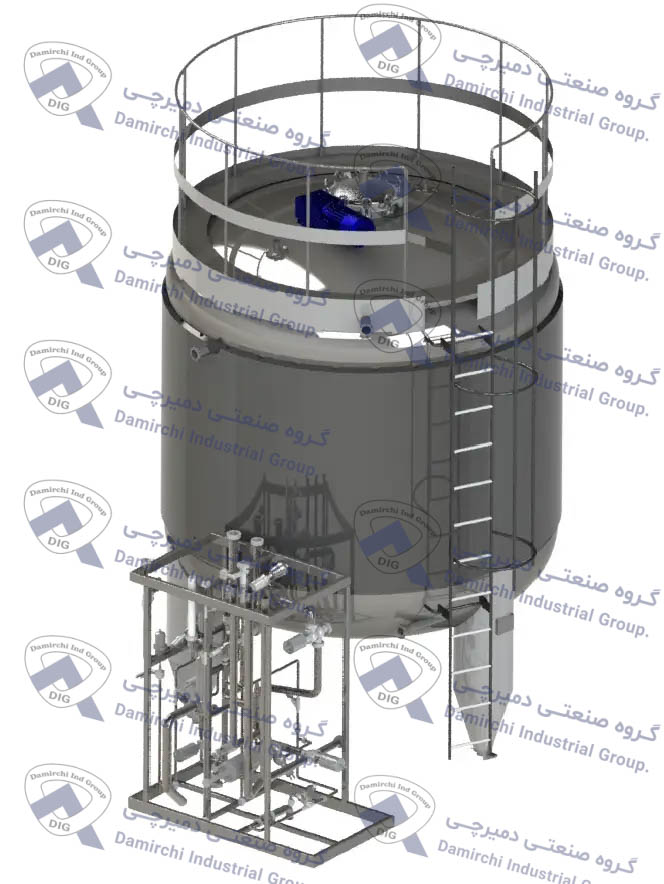

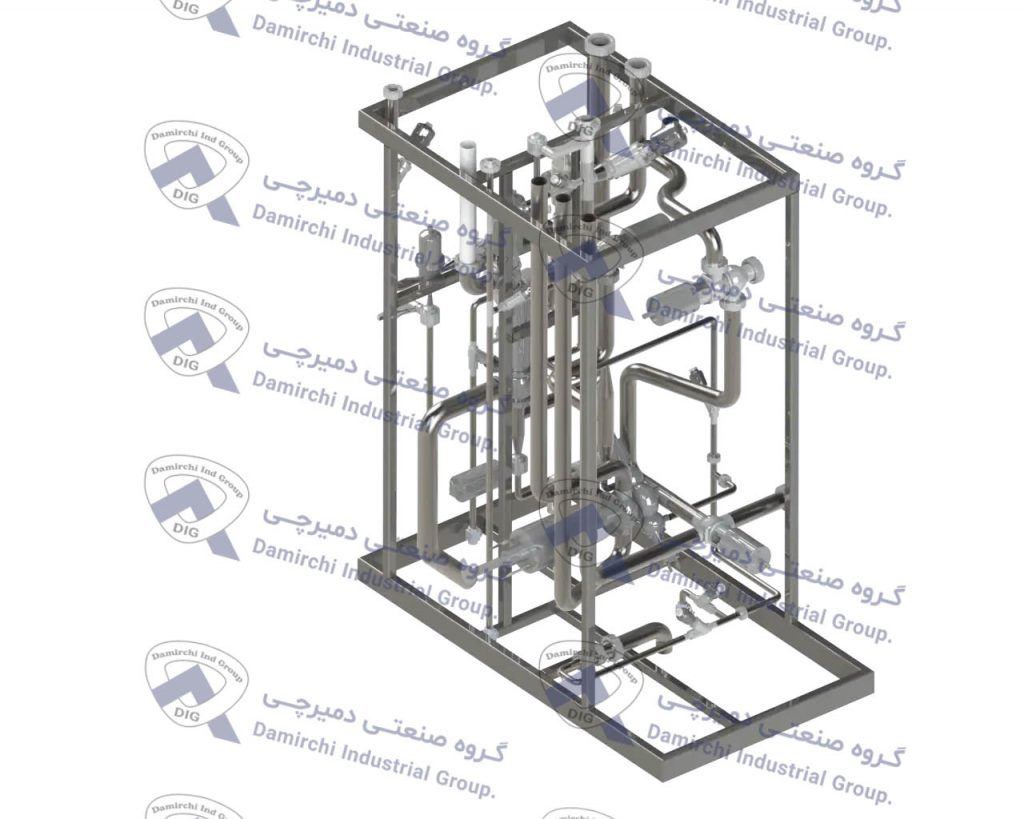

Steel tank 316-Steel tank 304:

Steel tanks in grades 304 and 316 are the most widely used tanks in various industries due to their good metallurgical properties. The properties of the steels, including impact resistance, tensile and physical properties, resistance to high and low temperatures, etc., play an important role in the quality of construction of steel tanks. Excellent corrosion resistance properties of stainless steels against chemicals can be found in their percentage of chemical analysis in relation to the presence of alloying elements such as Cr = 18, Ni = 8, C = 3%, Mn = 2, Si = 0.75. The metallurgical function is such that when corrosive substances attack the wall of steel tanks, the element Cr = 18% enters into action and protects the surface, and because chromium is inherently self-healing in the environment, it plays an important role in the resistance of tanks. The metallurgical function is as follows: by corrosive attacks to the tank wall, Cr=18% protects the surface and Chromium plays an important role in resistance of tanks for its self-healing properties.