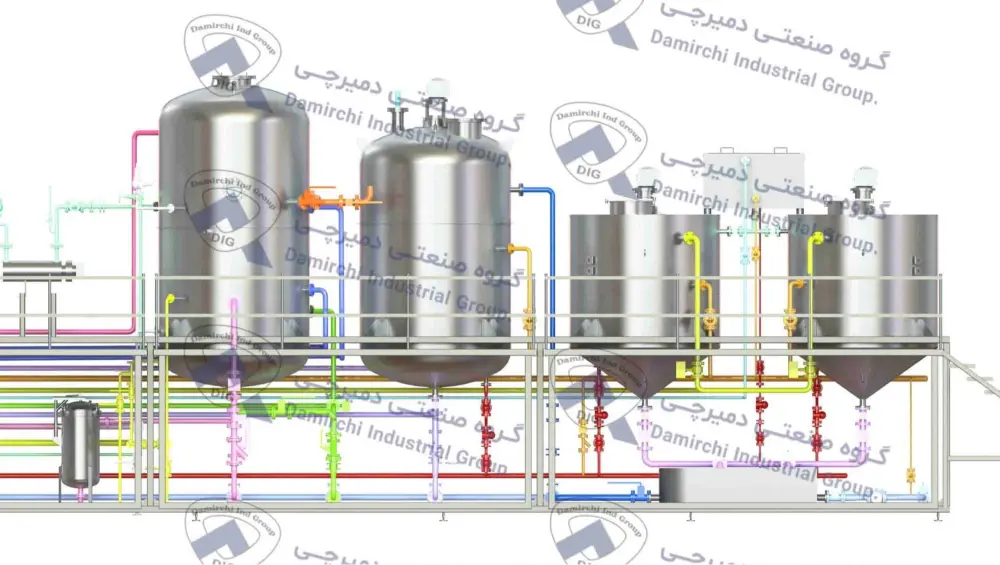

2- Neutralization

In the second stage of refining, by injecting phosphoric acid into the crude oil at a rate of about one kilogram per ton, all the remaining gums, which can be hydrated with acid, are also hydrated and form a separate phase. At the next step, caustic soda is injected into the oil; this injected caustic soda neutralizes the excess amount of phosphoric acid of the previous stage and also saponify all the free fatty acids in the oil which will form a separate phase as well. The amount of injected caustic soda at this stage is calculated by measuring the amount of free fatty acids in the crude edible oil and taking into account about 20 to 25% of excess one. There after injection of the caustic soda and passing it through the retention tank, the hydrated gums in the previous stage and the fatty acids which neutralized with caustic soda form a heavier phase than the edible oil and are separated from it by a centrifugal separator, which is called soap stock. Then, oil will wash with water by injecting hot water to the oil and mix completely with it to wash the remained soap from oil, this water is then separated from the oil by a separator as well. The water washing step could be repeated twice in the edible oil production line. At the last step, a vacuum dryer is used to separate the remained water in the oil after washing step, at last, oil is directed to the tanks of neutral oil.