Damirchi Industrial Group with latest technology is active in the field of turn-key plants for the production of starch and sweeteners from corn and other raw materials.

There is a brief introduction of production process of starch and sweeteners, equipment and machinery used in production line and their features as below:

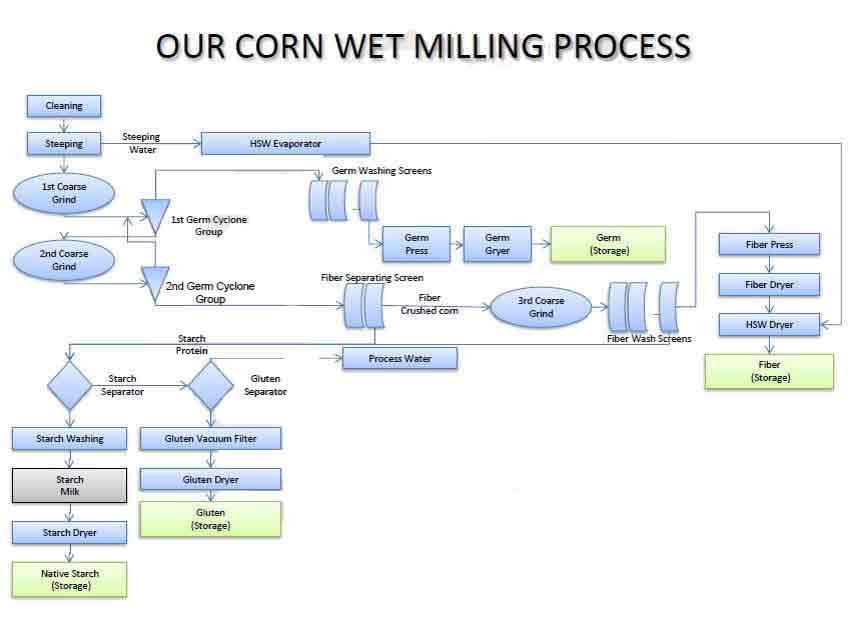

The pre-cleaned corn from silo is transported by elevator to the cleaning machine and broken corn and dust are screened off.

The cleaned corn is passed via a magnetic drum separator to the desanding tank which contains light steep water for hydraulic transport to the steeping vessels. Heavy particles, such as sand or stones, settle to the bottom of this tank.

The corn transportation water (thin steep liquor) is preheated in a heat exchanger to maintain approx. 50° C. After the steep tank is filled the steeping time is counted for soaking the corn in the steep water for approx. 48 hours. The water of each steep tank is continuously circulated through a tube heat exchanger to maintain the steeping water at 50° C temperature. The ready steeped corn is passed through a stone catcher and is dewatered on an arc screen before milling.

Light steep water with approx. 4-5 °Be is containing lactic acid bacteria and various soluble substances. It is added to the feed (hulls and fibers) prior to drying with a concentration of 50% DS. The light corn steep liquor will pass a strainer and will enter an evaporator to reach concentration of 50% DS.

The degermination is achieved in two stages. The steeped corn is dosed by a feeding device to the first grinding mill to be broken. The germ is released from the ground corn in an agitated tank. The germs are separated from the ground corn in the first stage of the two-stage hydrocyclone degerminator and are fed to the germ washing screen. The underflow of the hydrocyclone degermination is passing stage two and then dewatered on arc screen and ground a second time in a 2nd grinding mill.

The dewatered germ(at approx. 55% moisture) is discharged into a screw conveyor feeding the steam tube bundle dryer. Here the moisture content of the germ is reduced to 5%. The dried germ is discharged to germ silo.

The degerminated corn slurry is pumped into an arc screen for dewatering to reduce the hydraulic load on a fine mill which mills the dewatered fiber to release starch and protein from the fibrous parts of the corn. The washed fibers are pre-dewatered on an arc screen before dewatering, i. e. final dewatering in a fiber press to approx. 60% moisture content.

The pre-dewatered fiber is mixed with concentrated corn steep liquor in a feed mixer and is then transported by a screw conveyor into a bundle tube dryer to be dried to approx. 12% moisture content. The dried animal feed is dosed by a rotary air lock into conveying system and transported to the feed silo.

Starch recovery is the main goal of wet mill processes. For this aim screens have great importance in terms of efficiencies. In multiple stage wash screens the starch sticked on fiber and germ is washed by process water.

Types of screens:

The mill starch from the 3rd mill de-gritting screen is filled into the mill starch tank and then is passed through a rotary brush strainer to the mill starch thickener separator (MST separator). The starch and gluten particles are separated from excess water to produce more concentrated (thick) starch and gluten solution.

Concentrated starch and gluten solution is sent to primary separator (starch separator) feed tank. The starch particles, in the primary separator are partly washed by water which is injected by a pressure pump. A centrifugal pump transfers refined starch to the starch dewatering/drying section and another to the glucose/maltose plant.

Nozzle type sparators will be used as Primary Separator, MST, and Gluten Concentrator in the wet mill process.

These high speed machines will be supplied by well-known European suppliers.

The gluten containing overflow from the primary separator is concentrated in a separator which separates by centrifugal force the heavier gluten particles from the water phase. The gluten is dewatered in rotary vacuum drum filters to approx. 40% DS and then continuously fed to the gluten dryer.

The dewatered gluten is passing a feed mixer before entering to the steam tube bundle dryer. The dried gluten at approx. 12% moisture is discharged continuously into a hammer mill to be milled to a uniform size and is then dosed to the gluten silo.

Refined starch slurry(at 38-40% DS) is dewatered on a peeler centrifuge and then dried in a pneumatic flash dryer to approx. 12% moisture content.

The dried starch is transported to the starch storage tank nearby. A bin discharger feeds the starch into the bagging scale and packed as 25 kg bag final product.

Paper Sacs – All the starch will be stored in a Bin and then fed to the automatic bagging machine. These machines are fully automated, with electronic check weight.

Big Bag – 1.0 ton. This pack is more and used by Industries, so the Packing House shall be prepared to handle them. There will a conveyor system for transportation and storage of Big Bags.

All the sacs and bags will be transported via Conveyors and are weighed checked by a Check Weigher, after that they will be labeled with an Ink Jet automatic printer.

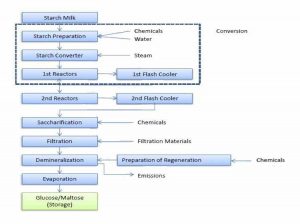

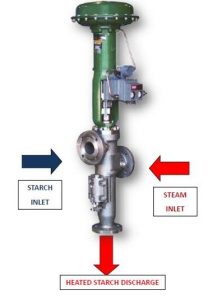

Liquefaction: the starch molecule can be considered as a long branched chain with several thousand links made of sugar molecules. If the links are broken, a mixture of sugars(syrup) will be formed. After the starch milk is prepared from starch arriving directly from the starch plant, it is automatically PH-adjusted and alpha-amylase is added by dosing pump. It is then transferred to the liquefaction section consisting steam jet heater, retention tube and reactor. The hydrolysate is passed through liquefaction tubes for further reaction of the enzymes for about 2-3 hours and then transferred to the saccharification section.

The syrup from liquefaction is cooled and the pH is adjusted before dosing of the Saccharification enzymes.

The reaction is finished in a series of saccharification tank reactors where the product is converted into glucose, maltose or dextrose syrup.

The color bodies, proteins and fat, which have their origin in the starch, can be removed partially by micro filtration called as pre-coat filtration system. The particles become coated with the adhering color bodies and residues and are then separated from the syrup. The hydrolysate is then fed to demineralization to remove residual impurities.

After pre-coat filtration the clear glucose solution contains still dissolved organic and inorganic impurities, mainly minerals, derived from the raw material and from chemicals added to the product at previous process steps. Most of these substances are present in partially ionic form according to dissociation balance.

Two sets of cation and anion exchangers are provided, which are operated alternately, the second set being regenerated or in stand-by position. The solution is passed on from cation to anion exchangers by pressure difference. The ion exchanged solution is passing a mixed bed ion-exchanger at the final end for polishing of the glucose solution.

There is a storage tank for vapor condensate obtained from evaporator plant. The tank for recuperation water is collecting regeneration water obtained from the 2nd wash and/or forward wash of the ion exchanger regeneration.

Caustic soda tank, hydrochloric acid tank, CIP-tank and waste water tank have to be foreseen for various process requirements, like ion-exchanger regeneration, CIP cleaning and waste water neutralization.

The glucose solution is concentrated to the desired dry substance by an evaporation station operating under vacuum taking care of the product quality.

The final concentrated and tested glucose product is stored in storage tanks. The tanks have a heating coil on the bottom and shell side in order to keep a certain product temperature or for increasing the temperature of the product during unloading.

Preconcentration of glucose: the glucose solution is concentrated to the desired dry substance by a falling film evaporator comprising several stages in a continuos series. All stages operate under a vacuum and the vapors are used in the next stage to heat the product for further evaporation. The glucose in the last effect is degasified to be oxygen free.

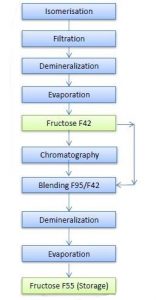

In isomerization, glucose is converted to fructose isomers under catalytic equilibrium reactions. DS, temperature, PH and chemical composition of some elements adjusted. Sodium- meta- bisulphite, magnesium-sulphate and sodium hydroxide influence the enzyme activity and stability as well as by- product formations.

Two sets of cation, anion and absorber exchangers are provided, which are operated alternately. In the cation exchangers metallic ions are removed in the anion exchangers acid radical ions, soluble amino-acids and color bodies(HMF) are removed and in the absorber especially HMF and color is removed. Finally high quality fructose syrup is obtained, which is absolutely required for a long resin life time.

Intermediate evaporation is carried out in a vacuum evaporator to a standard concentration of about 60% DS. The evaporation procedure is as dextrose description. When the final concentration is achieved the syrup is passing through a plate cooler to be cooled down to about 35°C and sent to the fructose enrichment plant.

The water and syrup for the chromatographic system require certain parameters:

Temperature, free of ionic components, free of microorganisms, free of oxidizing agents, free of oxygen, conductivity less than 10 microsiemens. This is to avoid deterioration of the resins and to ensure a good product quality.

the fructose separator serves as a system for separating to liquids from each other in this case glucose and fructose solution. In this field, the most cost effective solution is to produce by chromatography fructose syrups at about 90% purity, and to blend it with HFCS 42 syrup in such a ratio that HFCS 55 is obtained. The raffinate fraction produced by the chromatography can be used upstream into the isomerization step, in order to improve the global process yield.

Blending a 90% F solution and a 42% F solution results in a 55% HFCS solution. This is done in stirred tanks equipped with load cells, where the respective amounts of each fraction are pumped into obtain the 55% fructose content. When the system operates at steady equilibrium, lab analysis may not be needed for every batch.

The HFCS 55 syrup is led to mixed bed ion-exchangers for removal of traces of color, HMF and other ionic impurities.

Final concentration of 55 fructose solution is carried out in a vacuum evaporator to a standard concentration of about 77% DS.

The concentrated HFCS 55 syrup is stored in storage special tanks. These storage tanks should be kept under controlled temperature conditions in order to prevent any kind of fermentation.

Hydroheaters operates smoothly to ensure condensation happens immediately. Other less complicated heaters do not modulate steam. The result is surging or uncontrolled operation, inconsistent temperature, fluid damage, and downstream interruption. Direct steam injection hydroheaters use all of the energy within steam, both latent and sensible, to heat the fluid. Comparably, a heat exchanger system frequently does not return condensate to the source. Heat is lost in return systems and those systems use energy as well.

Glucose syrup is mainly produced by first adding acid or enzyme α-amylase to a mixture of corn starch and water.

Acid or enzyme breaks the starch into oligosaccharides.

All process parameters like pH, temperature, DS, flow and pressure are controlled fully automatically.

The syrup from liquefaction is cooled and the pH is adjusted before dosing of the Saccharification enzymes.

The reaction is finished in a series of saccharification tank reactors where the product is converted into glucose, maltose or dextrose syrup.

Full automatic step vice knife system

By means of a control panel all system controlled automatically.

High efficiency color removal system using Anionic/Cationic Resins of high a

High efficiency color removal system using Anionic/Cationic Resins of high absorption.

With life span of more than 2 years if well reactivated and well cared.

Automated backwashing, resin recovery and retention.

bsorption.

With life span of more than 2 years if well reactivated and well cared.

It has been equipped with the latest technology automation equipment and sophisticated scada systems, from which the volume of the product feeding into the system, energy input, the volume of output product, body heat, and system pressure and other critical process parameters are observed through the operators’ screen and are automatically controlled

The separator is designed as a stainless steel column with multiple chambers, arranged in an endless loop, and filled with special resins.

The system is equipped with an high-end control system, in order to get highest yields and quality.

Once F95 is separated, F95 & F42 will be blended to get F55.

The cooling crystallizers are used for the crystallization of fructose, dextrose and special sugars.

To meet the high quality standards for the production of crystalline products, all components that come into contact with the product are made from stainless steel.

Damirchi Manufacturing and Industrial Group was established with the aim of enhancing quality levels and execution standards in the design, construction, installation, and commissioning of machinery for the food, pharmaceutical, and chemical industries. The group’s activities in food machinery include the setup of oil production lines, dairy production lines, and more.