Milk Reception

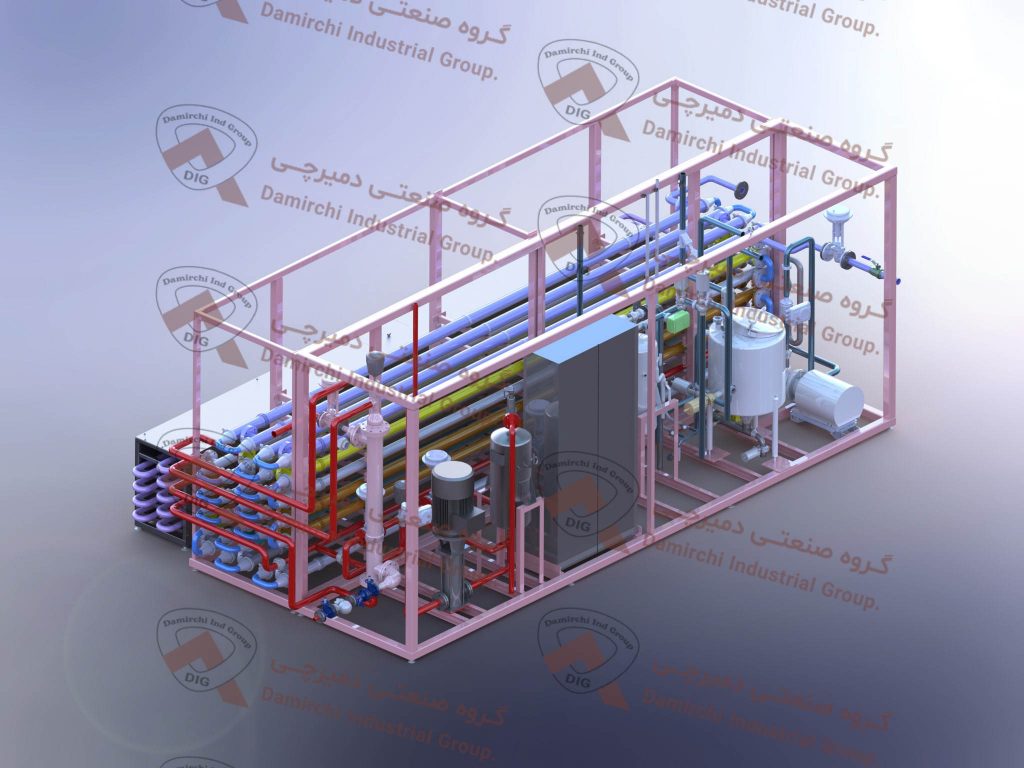

Milk Reception Area, as the first processing stage, is designed to convert the received Raw Milk to Pasteurized Milk and Cream.

Damirchi Industrial Group is active in the field of construction and operation of various production lines and dairy factories and has recorded many successful projects in its portfolio inside and outside the country.

Trucks arriving at the dairy drive straight into the reception zone. Since mechanical treatment is not favorable for unpasteurized milk due to possibility of lipolysis, unloading by gravitation is preferred. That is why in many industrial plants equipment to do with milk reception are mounted in the basement

The pasteurization of milk is a special type of heat treatment which can be defined as “any heat treatment of milk which secures the certain destruction of tubercle bacillus (T.B.), which is the most resistant pathogenic organism existing in the milk, without markedly affecting the physical and chemical properties”. T.B. is considered to be killed by heating milk to 72-75°C for 15-20 seconds. T.B. is therefore regarded as the index organism for pasteurization: any heat treatment which destroys T.B. can be known to destroy all other pathogens in milk. Apart from pathogenic micro-organisms, milk also contains other substances and micro-organisms which may spoil the taste and shorten the shelf life of various dairy products. Hence a secondary purpose of heat treatment is to destroy as many as possible of these other organisms and enzymatic systems. Since phosphatase enzyme is always present in the raw milk and it is easily removed during pasteurization process, its absence can confirm the pasteurization process.

The pasteurized milk from pasteurization unit is sent to the tank farm. Tank farm must be capable to accommodate milk with different cream content for further processing in other unites. The amount of milk sent to other units is usually measured by flow transmitter mounted on the sending lines.

A typical dairy CIP program consists of following steps:

Rinsing with warm water for about 10 minutes.

Circulation of an alkaline detergent solution (0.5 – 1.5%) for about 30 minutes at 75°C.

Rinsing out alkaline detergent with warm water for about 5 minutes.

Circulation of (nitric) acid solution (0.5 – 1.0 %) for about 20 minutes at 70ºC.

Post-rinsing with cold water.

Disinfection can be done in the morning, immediately before milk processing begins. This is typically done by circulating hot water at 90 – 95°C for 10 –15 minutes after the returning temperature is at least 85°C.

According to the design and capacity of the CIP unit, different configurations are possible; for example a CIP center can have in-line heaters or heaters mounted on the circulation circuits made for each tank. The most comprehensive design of a CIP center consists of five tanks for Acid, Soda, Sterile Water, Fresh Water and Recovery Water. However, the best design should be tailored made specifically for each project.

Generally, there are two types of Sterilizers; Direct Sterilizers and Indirect Sterilizers. In Direct Sterilizers food grade steam is injected into the milk and raises the milk temperature to 140-150◦C. The milk is held at this temperature for 8 seconds before being cooled down. Pre-cooling is performed in a tubular heat exchanger where the heat energy is utilized for regenerative heating. The injected steam is flashed off as vapor in a vacuum vessel and the milk temperature drops to 80◦C simultaneously. After aseptic homogenization, the milk is cooled to almost 20◦C.

In indirect Sterilizer the milk is heated up to 110◦C through regenerative heating and then in the heater section, after exchanging heat with the pressurized hot water, it is heated to 135◦C and then after, again it is cooled down through regeneration. There are 2 holding times in this type of heat treatment; one for 90 sec at 90◦C (upstream of the main heater) for protein stabilization, and the other one at 135◦C for fulfillment of sterilization process. Homogenization should be at 75◦C, however, if downstream is selected to place the homogenizer, the aseptic one must be chosen.

When coming to required conditions for long life milk, Aseptic means “No Connection with the intimate environment”. By exerting high pressure sanitary air above the aseptic tanks and aseptic fillers, this connection has been brought to the minimum. Thus, in case of any unwanted interfaces between the processing equipment and the intimate environment, products will be kept unaffected by the surrounding.

Some people suffer from lactose intolerance. As a result, lactose is not broken down in the digestive process into simpler types of sugars. These people can consume only very small volumes of ordinary milk. They can however consume cultured milk, in which the lactose is already partly broken down by the bacterial enzymes.

There are many kinds of yogurt. In the following sections the production procedure of stirred and set types are reported. The main difference between these two types lies in fermentation step. The set yogurt is incubated and cooled in the packages. When pre-treatments are applied, the starter culture is inoculated and the product is filled in the packages or cups roughly at 45◦C. The packages or cups are kept in an incubation room. When the fermentation process is completed to reach an adequate taste and flavor, the packages are transferred to a rapid cooling room to cool the product settling the fermentation process down. However, in case of stirred type, the yogurt is fermented in tanks and cooled before packaging. So the final product is ready when packaging is completed.

This production procedures are mainly consisted of three steps; Mixing, Pasteurization and Packaging-Storage.

Since yogurt has many different ingredients in solid and liquid phases, mixing is of prime importance and must be carefully performed. After dosing different liquid ingredients as well as, pasteurized milk, pasteurized cream, UF retentate… into the mixing tank, solid additives will be added and mixing will be accomplished in tanks using agitators. Different quality in different packaging may come from incomplete mixing and that’s why the complete mixing has a paramount role in high and constant quality of the final product.

From the balance tank the milk is pumped to heat exchanger (pasteuriser), where it is first preheated regeneratively to about 70°C and then heated to 90°C in the second section. From the heat exchanger the hot milk flows to vacuum vessel, where 10– 20% of the water in the milk is evaporated. After evaporation the milk continues to homogeniser and is homogenised at a pressure of approx. 20 – 25 MPa (200 – 250 bar). The homogenised milk flows back through the regenerative section to the pasteurisation section of heat exchanger and is reheated to 90 – 95°C. The milk then flows to a holding section dimensioned for a holding time of 5 minutes. After pasteurisation the milk is cooled, first in the regenerative section and then with water, to the desired inoculation temperature, typically 40 – 45°C or, if set yoghurt is to be produced and the pre-treatment capacity does not match the packing capacity, to a temperature below 10°C, preferably 5°C.

The incubation tanks are insulated to ensure that the temperature remains constant during the incubation period. The tanks can be fitted with pH meters to check the development of acidity. In typical production of stirred yoghurt the incubation period is 2.5 to 3 hours at 42 – 43°C when the ordinary type of bulk starter (2.5 – 3% inoculum) is utilised. To attain optimum quality conditions, cooling to 15 – 22°C (from 42 – 43°C) should be accomplished within 30 minutes after the ideal pH-value has been reached to stop further development of bacteria. At the same time the coagulum must be subjected to gentle mechanical treatment so that the final product will have the correct consistency. Cooling takes place in a plate heat exchanger with special design. This ensures gentle mechanical treatment of the product. The capacities of pump and cooler are dimensioned to empty a tank in 20 – 30 minutes in order to maintain a uniform product quality. If cultures with other fermentation curves are utilised, which may have an influence on the incubation time, the cooling time should be adapted in view of that. The cooled yoghurt is pumped to buffer tanks before being routed to the filling machine(s).

As stated earlier, in case of set yogurt production milk will be treated in the same way as for stirred yoghurt, however, it will be cooled to a temperature of less than 10°C, preferably to 5°C, and will be pumped into one, two or more tanks. Following inoculation and thorough stirring, the milk is ready to be heated in-line to incubation temperature before being packed in containers (fermentation is carried out in packages). Bulk starter culture can also be added in-line prior to heating to incubation temperature.

In case of stirred yogurt production, packages will be transferred to the cold stores and will be kept at 5°C. But in case of set yogurt, the filled packages/containers are placed in crates of open design and at a certain distance from each other so that the circulating warm/cold air for the incubation and cooling room or chamber can reach every individual container.

The crates are normally stacked on pallets, which are then trucked into the incubation room. This ensures uniform quality, provided that the temperature is accurately controlled. When the empirically determined optimum pH (typically 4.5) is reached, it is time to start cooling. The normal target temperature is 18 – 20◦C; it is important to stop further growth quickly, which means that a temperature of about 35◦C should be reached within 30 minutes, and 18 – 20◦C after another 30 – 40 minutes.

In a typical incubation period of 3 – 3.5 hours, it is very important that the product is not exposed to any mechanical disturbance during the last 2 – 2.5 hours, when it is most sensitive to the risk of whey separation. The cooling capacity should be adequate to achieve the above mentioned temperature program. As a guide, it may be mentioned that the total cooling time is about 65 – 70 minutes for small packages (0.175 – 0.2 kg sizes) and about 80 – 90 minutes for large packages (0.5 kg size). Eventually, regardless of the type of incubation/cooling chamber, the set yoghurt is cooled to about 5◦C in the chill store.

There are two different methods to produce fermented milk drink (doogh); it can be produced from fresh milk or it can be produced from yogurt. Below, the required process for the first approach is reported (Doogh production using fresh milk).

Firstly, the standardized milk containing 1.5% fat is pasteurized at 85◦C and after being cooled down to 45◦C it will be transferred to fermentation tank. Secondly, water, as much as pre-processed milk, will be pasteurized at the same condition and will be added to the fermentation tank. Thirdly, solid materials as well as salt and culture, will be fed the fermentation tank. The tank content will be stored in the tank as long as the favorable pH is met. Lastly, this tank content will be directed to the pasteurizer for the second pasteurization. After being pasteurized at 85◦C, product will be cooled down to 4◦C. The final product is ready for packaging.

Firstly, all liquid constituents, as well as pasteurized cream and milk are dosed into the buffer tank. After complete mixing of these ingredients, temperature of the mixed liquid will be increased to 60◦C after passing through a plate heater. Then the preheated liquid stream will be directed to the main mixing tank. In this step, solid ingredients as well as sugar and milk powder will be added to the tank for homogenization. In the next step, the homogenized mixture will be pasteurized at 85◦C and 15 seconds and will be sent to the ageing tank. In ageing tank, concurrent with slow mixing and ice water flow in the jacket, the required time for reactions between proteins in the milk with water is provided (almost 4 hours). This leads to better mixing of air and better resistance of ice cream against melting. Finally, the final mixture will be sent to the freezers and packaging machines.