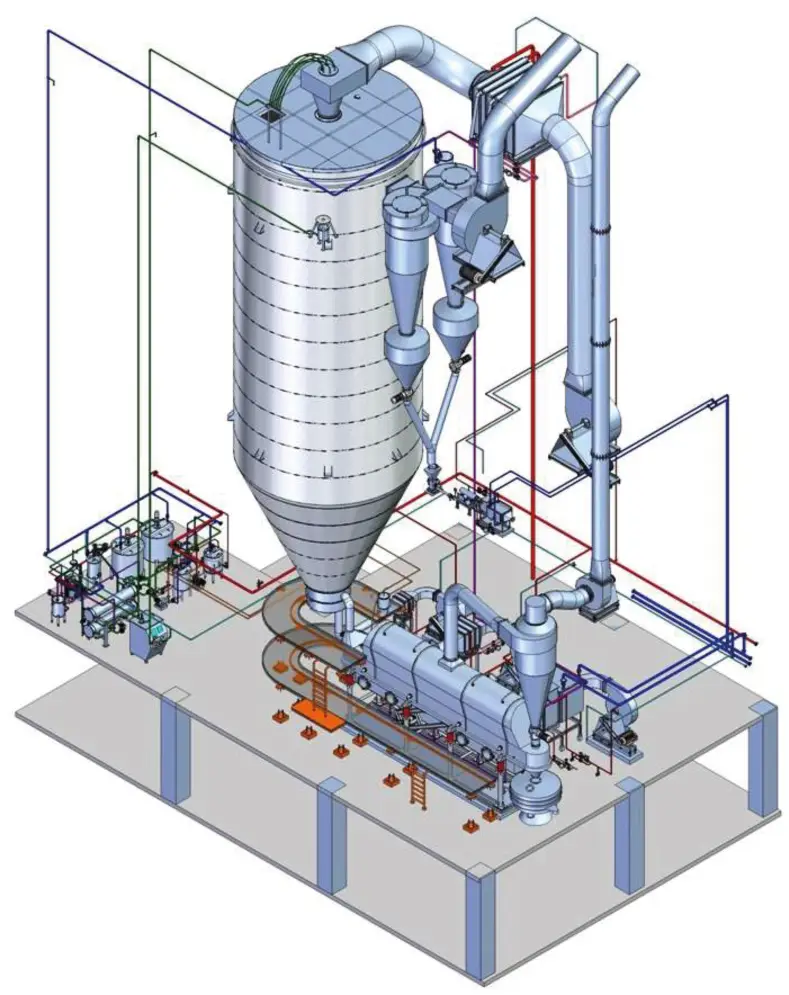

Evaporation

Before converting the product into the powder, the liquid feed should be thickened as much as possible through expelling the extra water. This thickening process occurs in multi-effect evaporators in which, by making a vacuum pressure, boiling temperature is reduced. The greatest advantages of falling film evaporators are heat recovery and mild processing condition. As a general heuristic, their energy consumption is only 100-300 kWh.t-1 of removed water (or even less), whereas it is about 1000-2000 kWh.t-1 for spray drying towers.

Milk enters the evaporation unit from the balance tank. From there, milk is sent to the thermophilic preheater to be preheated up to ~70°C. Then, milk should be pasteurized at 80 – 85°C. The used pasteurizer in this design is a direct pasteurizer in which steam is directly admitted into the feed. After passing through the holding tubes, pasteurized feed, will be directed to the flash vessel in which the injected steam is separated. Actually, the separated steam in this vessel was reused in the thermophilic preheater previously. Then after, the feed enters the calendria of evaporators from the 1st stage to the last stage respectively and gets concentrated. According to the design of the plant, only a small fraction of required steam is provided from the boiler room and the major heat requirement is provided by the reuse of produced steam in each step in the next coming step to enhance economy of the plant. A great milestone in design of evaporators is the design of calenderia. Although reduced boiling point decreases possibility of scales in calendria, but every single extra square meter in area of calendria causes 150 gram extra fouling in a day; the more fouling means more product loss and more production stoppages. In dairy industry, evaporator effluent should include a solid content of 45-55% according to type of the product.

Before converting the product into the powder, the liquid feed should be thickened as much as possible through expelling the extra water. This thickening process occurs in multi-effect evaporators in which, by making a vacuum pressure, boiling temperature is reduced. The greatest advantages of falling film evaporators are heat recovery and mild processing condition. As a general heuristic, their energy consumption is only 100-300 kWh.t-1 of removed water (or even less), whereas it is about 1000-2000 kWh.t-1 for spray drying towers.

Milk enters the evaporation unit from the balance tank. From there, milk is sent to the thermophilic preheater to be preheated up to ~70°C. Then, milk should be pasteurized at 80 – 85°C. The used pasteurizer in this design is a direct pasteurizer in which steam is directly admitted into the feed.