Pasteurizers are devices that are able to completely destroy the cell bacilli by applying heat to the milk without any other adverse and unfavorable effect on the milk. Since bacilli are the most resistant pathogens in milk, the elimination of other pathogens is also evaluated.

The tubercle bacillus dies at a temperature of 75 ~ 72 C ° and a time of 16-20 seconds. Apart from pathogenic microorganisms, milk contains microorganisms that also have a detrimental effect on the taste and shelf life of other dairy products.

Therefore, the purpose of the pasteurization process is to eliminate these microorganisms. Since phosphatase enzyme is always present in raw milk and this enzyme is easily eliminated by raw milk, the absence of phosphatase enzyme in pasteurized milk confirms the correctness of the process.

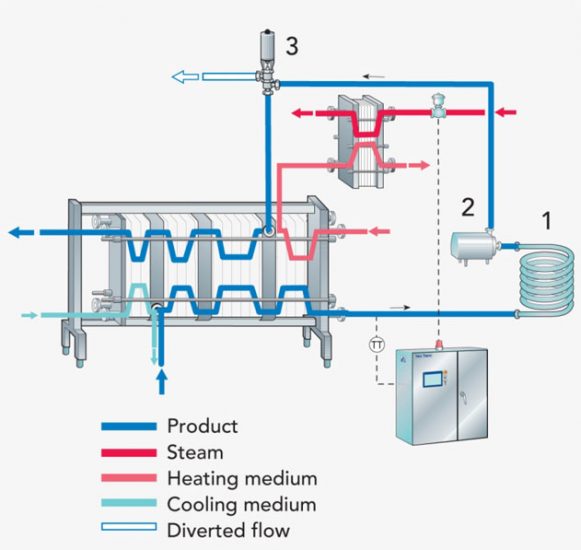

The milk received from the raw milk unit first enters the tank balance. The control of the hot valve level inside the balance tank can be controlled both mechanically (with the help of a floater) and by using pneumatic valves and relevant precision instruments. The pasteurizer plate as the most important part of the device consists of 3 parts, heater, regenerator and air conditioner. Raw milk first enters the pasteurizer at 4C temperature from the Regeneration section and while regenerate the heat of pasteurized milk, it is heated to 60 ° C. Then at this temperature, the milk enters the heater section and while exchanging heat with hot water, it is heated to a temperature of 75 ~ 72 C °. The heated milk then passes through the holder to allow 16-20 seconds to eradicate the microorganisms, according to the Pasteur standard, such milk is now free of undesirable microorganisms. The pasteurized milk re-enters the heat recovery section and cools its inlet valve to about 14 ° C while preheating. In the last part, by passing through the cooler section and dissipating heat to the ice water flow, the milk is cooled to 4C temperature. Click on the below link to see complete information about dairy production lines.

The operation of these devices has 3 phases, production, CIP, SIP.

At the end of the production phase, which usually takes up to 8 hours, due to sediment in the pasteurizer plate, the machine is no longer able to reach the desired temperature and the line must be washed. Since pasteurizers are CIP by themselves (and not by CIP Center) unlike other equipment, it is necessary to anticipate an Alkali and acid dosing system in these devices.

Finally, it is time to sterilize the device, which is always done in the initial production. In this way, by turning the hot water in a line with a temperature of 90 ~ 95 C ° for 10-15 minutes, first the whole mixture is sterilized and then after adjusting the temperature, milk is received. Click on the link below to see complete information about the fully automatic CIP unit