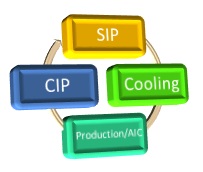

Working Principles

A complete operational cycle of aseptic tanks starts with Sterilization In-Place (SIP). Sterilization of aseptic tank is performed using direct use of live steam at 125°C for 30 minutes. After sterilization, the body of the tank should be cooled down slowly to prohibit any negative impact on the final product. To do so, a very mild flow of soft water will be injected in cooling jacket of the aseptic tank. In the early seconds of this cooling step, a great share of the injected soft water will change to steam and will leave the jacket. In order to prevent any vacuum formation in tank during cooling process, pressurized aseptic air will be used.