Description

Chips and Olivier Production Line

Damirchi Industrial Group is able to design and build chips production factory including a variety of potato chips production line such as Regular chips production line, Stackable potato production line, French fries production line and Olivier potato salad (Russian salad) production line and has been operating at home and abroad several large projects. Company is completing its projects using technology from the largest leading chips manufacturing companies such as H&H, heat & control, and FMC. Below are the machineries and equipment of this company in design and manufacture of various chips factories along with the general stages of potato chips production. Click on the buttons below to read each of the chips lines.

Regular Chips production line

Steps to make Regular chips

Potatoes after get sized, cleared from mud, then send to storage room for saving and depo-off in order to increasing and preparing in specific circumstances (temperature, humidity, light) for going to process.

In this step, potatoes are sorted, washing and clearing from any contamination completely by drum and tunnel.

1- Bucket Peeling Machine: The potato slips into the body with centrifugal force causing the skin to peel off

2- Roller Peeling Machine: Rollers which moving pairwise in opposite direction and causing abrasion and finally separation peel from potato without any physical impact.

Potatoes are separated and reviewed to not including any green part or excess peel.

In this step potatoes impact to 8 blades by centrifugal force causing slices with determined thickness. FAM Belgium.

In this step, surface starch of slices separate by floating in water at 30 C and abrasion to each other.

Slices were floated in water at 70 C and de-enzymised.

Potato Slices after blanching, lose water by continuous dryer and being ready for frying.

Potato slices completely fry in 1.5 minutes (depending on length and thickness) in edible oil at 180 C.

Potato chips were completely fried and crispy, after separation of burnt ones, get different flavors and after cooling go to packaging by conveyor belt.

In this step depends on product weight, product pack in bag by weight multi-head (10 or 14 heads). Note that in this step date and serial number write on bag by temperature date writer machine or jet printer. Also using nitrogen for increasing durability.

Regular chips production line machines

- Sorting machine

- Washing machine

- Bucket or roller peeling machine (8 rollers, PPM Sweden Model)

- Reviewing table

- Slicer machine 8 blades (FAM- Belgium Model)

- Drum Starch extractor

- Turbo belt blancher with equipment

- Continuous dryer with air circulation system

- Continuous fryer with heat exchanger and equipment

- Oil extractor machine

- Chips slices sorting machine

- Flavor machine

- Cooling tunnel

- Packaging machine (multi-heads)

French Fries production line

Steps to make French Fries chips

Potatoes after get sized, cleared from mud, then send to storage room for saving and depo-off in order to increasing and preparing in specific circumstances (temperature, humidity, light) before going to process.

In this step, potatoes are sorted, washing and clearing from any contamination completely by drum and tunnel.

Potatoes are peeled completely by high pressure steam peeling machine.

Potatoes are brushed and the rest of peel were taken from them.

The green and residual parts of the skin (potato pores) are completely separated. It should be noted that in this section large potatoes are separated and divided into smaller pieces.

Potatoes Cut to the Dimensions Required with High Pressure Pump by Hydro Cutter.

potatoes slices de-enzymised in two Blanching machine in specific time at 70 C.

Potato’s surface water is taken.

Slices are fried in edible oil at 180 C.

Slices are cooled after oil extraction, by cooling systems.

Slices are frozen at -30 C in specific time and then transfer to fridge room or packaging section.

French fries chips production line machines

- Hopper

- Washing system

- Steam Peeler

- Reviewing table

- Hydro cutter

- Sliver

- Primary and Secondary Blancher

- SAPP System

- Vibrator

- Dryer

- Fryer

- Heat exchanger

- IQF

- Boiler

- Steam Boiler

- Packaging

Stackable potato production line

Steps to make shackable potato chips

All raw material completely mix with few amount of potato powder in V-Blender.

In this step, rest of potato power is added to mix so that we get Homogeneous and uniform mixture.

In this machine, potato powder becomes dough with water and suitable additives, than will form to chopped dough.

Output dough Overspread and turned into a thin layer.

The dough comes out from sheeter, get molding and its surplusage turn back to dough mixer after chopping and drying. The rest will go to fryer as it is like chips slice.

The dough after molding completely fries in oil at 180 C then go out of it completely uniform.

Desired flavor goes on potato chips in determined percentage, then will guide to packing section.

This product can be packed in several packaging as customers order.

Shackable potato chips production line machines

- Day & Night tanks for discharging oil

- Stainless steel V-blender

- Ribbon blender

- Glassy Mixer

- Dough Machine

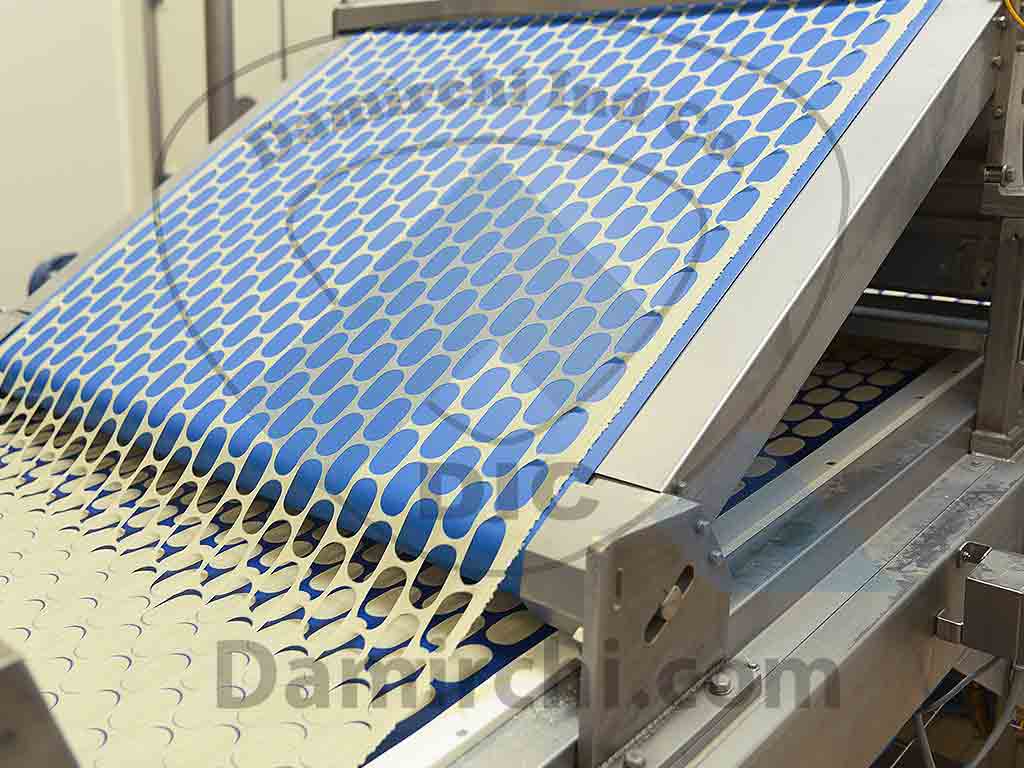

- Ribbon Belt

- Sheeter Machine

- Molding Machine

- Surplusage Transporter Belt

- Crusher Machine

- Returned material Collector

- Triple wall Mixer

- Water injection system

- Fryer & Pumps

- Flavor Machine

- Footer & Guide

- Packaging Machine

Olivier proction line

Steps to make olivier

Potatoes after get sized, cleared from mud, then send to storage room for saving and depo-off in order to increasing and preparing in specific circumstances (temperature, humidity, light) before going to process.

Potatoes in several stages are washed by fully automated machine and are cleared from any contamination.

Potatoes are completely peeled by scrubbing peeler.

Potatoes are separated and reviewed to not including any green part or excess peel.

Potatoes form to thin slices or small piece.

Surface starch were taken from slices.

Slices were floated in water at 70 C and de-enzymised.

Middle-boiled potato slices are completely change to well-boiled in autoclave with high pressure steam.

Boiled potato slices homogenously mix after adding sauce and additives.

Olivier production line machines

- Potato Lifting and Washing System

- Roller peeling machine (abrasion peeling)

- Roller revision device (Separating corrupt potatoes)

- Slicer machine

- Drummy starch extract machine (cold/ hot)

- Grid tank

- Autoclave and curing under vacuum and steam pressure

- Oliver mixer (two-shell)

- packaging

Reviews

There are no reviews yet.