Description

Sauce Production line

Ketchup production line

Ketchup is one of products which is very well known as flavoring and is being used with different types of foods. Dressings are divided into two groups by the production process:

- Cold dressings

- Hot dressings

In hot dressings’ production process the cooking process is one of the main parts but in production process of cold process dressings there is no cooking included and their main part of process is high speed blending process.

Ketchup is a product of concentrated tomato juice or diluted tomato paste with main and optional additives through a cooking process. The main ingredients in addition to the concentrated tomato juice or diluted tomato paste are sugar, vinegar, salt and optional ingredients are spices(e.g. chilly, black pepper, garlic, onion), allowed stabilizers(e.g. starch and gums)

1- Ketchup production process

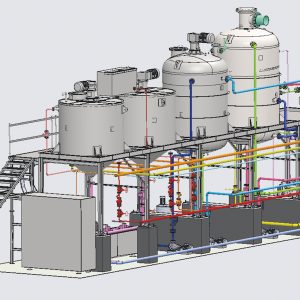

Modern principles for ketchup production include premixing, preheating of mixes, filtration, homogenizations, vacuum concentration, deaeration, heating up to required temperature, filling sterilized bottles and capping under completely hygienic conditions.

2- General description of ketchup production process.

In first phase of ketchup production process, tomato paste with 28-32 brix, sugar and water must be mixed and heated in precooking tank, then garlic, onion, spices and other additives will be added. After complete cooking process (vacuum or atmospheric pressure) the rest of mixture will be added to the tank. After initial cooking and concentration the mixture will go to the next step, here the vacuum is removed before adding salt and vinegar (in vacuum cooking method). Ketchup will be heated in atmospheric conditions in 93°C or more and incase required before transferring to the filtration stabilizers and emulsifiers will be added. Then the ketchup will go through pasteurization step. Ketchup will be transferred to the storage tanks with initial temperature of cooking and from storage tanks with high temperature will go to the filling, packing, labeling, and storage section. When this process is done the ketchup must be stored in quarantine conditions from one up to two weeks to check standard matching and assurance.

3- Designed process description

According to the existing terms and conditions, the whole process of ketchup production is as follows:

3-1- Ingredient reception unit

In this process ingredient reception unit according to the unit facility and customer opinion include:

- Tomato paste reception unit

- Vinegar reception unit

- Glucose reception unit

- Other

According to the method of reception (drum, tanks, or by pipping in tomato paste production lines) capacity and specification of ingredient of product reception in process line, some requirements will be considered for the unit.

Second section after ingredient reception unit will be vinegar reception unit that according to the method of reception, capacity and specification of ingredient of product reception in process line, some requirements will be considered for the unit.

Final reception unit in ketchup production process will be glucose reception unit. Required glucose for ketchup production can be supplied from outsources or we can prepare by mixing sugar and drinking water but generally it is suggested to use glucose for this process.

3-2- cooking

In process of ketchup production after ingredient reception unit, we have initial cooking section which is called precooking. This unit contains 2 tanks equipped with mixer and heating jacket. The tomato paste with 28-32 brix will be transferred to the mixing tank, then water will be added to reach the required brix. Mixing will be continued to reach required temperature (65-70 °C). There will be a uniform mix of tomato paste and water at the end of this precooking unit which will go through the second step which is called second cooking and the mix will be cooked in vacuum condition and high speed. Vinegar, dry compounds, powder form ingredients with accurate quantity measured in weighing unit will be added to the mix. The heating jackets in the tanks will heat the mixture up to 80-85 °C.

3-3-Pasteurization

When ketchup is ready after second cooking, it will be transferred to the storage tanks and then from storage tanks to the pasteurizer. For pasteurization of ketchup 2 methods can be done: direct pasteurization and indirect pasteurization. Indirect pasteurization is the common method for ketchup pasteurization and it is based on customer demand to choose this method. When the ketchup is going to be packed in bulk and in bucket for restaurants the method of direct pasteurization will be used. In direct pasteurization steam will be directly injected to the product. Indirect pasteurization process is designed as pipes and shell which the low pressure steam will be in the shell and ketchup in the pipes. For product pasteurization, ketchup will be held in 93°C in one minute.

3-4-deairiation

this unit is designed to remove trapped air bubbles in the ketchup and to make the texture of product more uniform. Another advantage of this unit is decreasing oxidation of product and increasing product shelf life.

3-5-Homogenization

This unit will decrease the dimension of fibers and it will make the product to be shiny. After homogenization the product will pass a filter with specific mesh size and will enter the filling unit with temperature of 90°C. One of advantages of homogenization unit is enhancing product stability. In case solid components are required to be added to the product such as chilly, before the filling unit.

3-6-CIP

The CIP unit contains 3 tanks for caustic, acid and sterilized water, also 2 lines for sending and 2 lines for receiving is designed. One of lines for sending will CIP the Ingredient reception unit and the other line will CIP precooking unit, second cooking unit, homogenization unit and filling unit. For more information of full CIP unit please visit below link:

Mayonnaise production

Mayonnaise production process is considered as cold process. Mayonnaise is a product which is from the emulsion of edible vegetable oil in liquid phase of vinegar. Oil in water emulsion will be created by yolk. Actually mayonnaise is a permanent emulsion of oil in water and it has milk taste and aroma, its PH from 3.6 to 4 which must not exceed 4.1.

In mayonnaise production, in addition to the edible vegetable oil, vinegar, egg, some ingredients such as flavours, salt, sugar, spices, gums, citric acid and etc. can be used.

1- General description of Mayonnaise production process

As already mentioned mayonnaise production process is in the category of cold process dressings and is discontinuous. For mayonnaise production, all ingredients will be fed into mixer homogenizer unit. In this unit all ingredients by priority and with specific dosage will be mixed together in vacuum and high speed mixing conditions. After the production is finished the mayonnaise will be transferred to the storage tanks and then will enter the filling and packing line.

2- Designed process description

According to the existing terms and conditions, the whole process of mayonnaise production is as follows:

2-1- Ingredient reception unit

In this process ingredient reception unit according to the unit facility and customer opinion include:

- Oil reception unit

- Vinegar reception unit

According to the method of reception (drum, tanks, etc.) capacity and specification of ingredient of product reception in process line, some requirements will be considered for the unit. In this process the capacity of reception unit will be calculated for the mayonnaise production of one day. The other ingredient which needs reception unit is vinegar. The capacity of this unit will be calculating considering the vinegar component dosage in the formula and the stability of vinegar.

After reception and storage of ingredients, this ingredients will be fed to the mixer homogenizer for one batch production.

2-2- Mixer homogenizer

Ingredients fed into mixer homogenizer will be stored in side tanks for this unit and based on product formulation these ingredients will be mixed together in different steps. Oil which is 80% of formulation content will be added to the mixer homogenizer tank in 4 steps and each step 20% of it will be added. In each step after adding oil, water, salt and sugar, egg, stabilizer and at the end vinegar will be added.

Please note that in the past the eggs were broken in separate room and then were transferred in the process but nowadays egg powders are being used which is more appropriate in flavor, texture and aroma comparing to the egg.

Mixing in homogenizer will happen in high speed and vacuum condition to produce a homogenized emulsion of mayonnaise. When the mixture is ready it will be transferred to next process phase.

For more information of mixer homogenizer unit please visit below link:

2-3- storage tank

The mayonnaise from mixer homogenizer unit will be stored in storage tank and then will be transferred to the filling, packing and labeling unit.

2-4- CIP

For CIP of mayonnaise production unit, one CIP unit including 3 tanks for caustic, acid and sterilized water, one line for sending and one line for receiving is also considered.

Contact us

Damirchi Industrial Group is able to supply sauce production line from A to Z. For more information about different types of sauces production line and to receive quotation please contact our experts.

Reviews

There are no reviews yet.